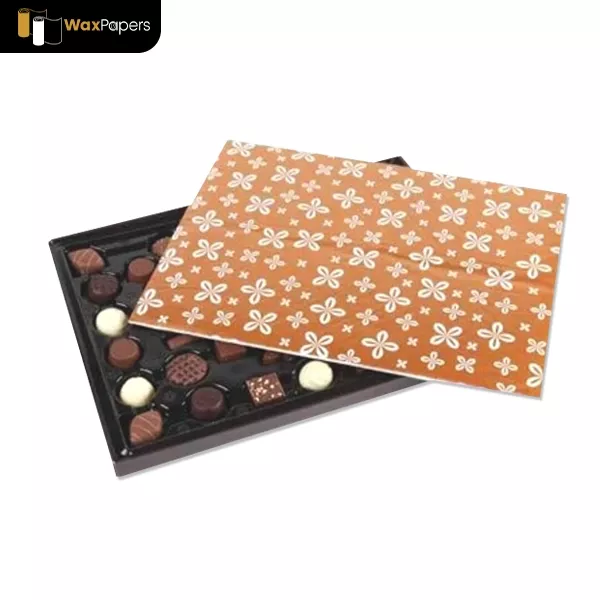

Custom Candy pads to present the Premium Confectionery

Small but significant parts in the packaging of confectionery products, such as custom candy pads, are a significant element in the protection, presentation, and integrity of the product. These pads are often placed under or between sweets and ensure no movement, receive small shocks and make everything in boxes look clean.

Gift vendors, candy companies and chocolatiers depend on them to give them products that would look as good as they taste. Candy pads should be carefully designed to boost the structure and perceived quality. Their significance is increased because rivalry between brands in a graphical market is based on presentation, consistency, and customer experience.

Support in Structural Packaging

One of the applications of candy box pads is offering a supporting system on which the sweets are stable throughout transportation and handling. This way, they ensure that the candies do not move or rub against the box walls by making a flat table. Such stability minimizes breakages and maintains decorative finishes. Pads are also used to keep things spaced in order to present them in a nice way. When the boxes are opened, products are seen to be well organized. This is a structural position that has a direct effect on a professional, high-quality unboxing experience.

Integrated Box Solutions

The most effective programs are candy boxes and pads created as a system. Interiors of the boxes are aligned to pad sizes to ensure the fit is tight. This integration improves efficiency at packing and also in making any adjustment to be made. It also standardizes inter-product line presentation. Consistency in the quality of the brands will be possible through a regular matching of the boxes and pads. The whole product appears to be more intentional and advanced when the elements are aligned to produce the perfect whole.

Surface Protection Layer

Glassine paper candy pads with logo have a smooth and non-sticky surface, which safeguards the finishes on delicate candy. This is due to their translucent nature, giving them a clean and polished appearance when packaged. These pads do not allow the transfer of oils or coating to the box. They also suppress the friction that may spoil chocolates. High-quality surface protection ensures the preservation of the products in terms of their appearance and freshness. This is an excellent layer which can be used on high-end or adorned confections.

Scalable Supply Options

Custom candy pads wholesale services serve brands that demand quality over time. Wholesale sourcing makes sure that there is consistency in materials in high production volumes. It also makes inventory management and cost control easy. Consistent bulk supply eliminates shortages at peak seasons. The advantages of brands are that there are no surprises in availability and maintenance. Wholesale alternatives help to expand without reducing the packaging quality.

High-Volume Efficiency

Custom candy pads bulk ordering is the best option for manufacturers and distributors with consistent output. Bulk makes available a lower cost per unit, and replenishment cycles are minimized. It also guarantees that all batches have the same materials. This compatibility can be used to assure quality and brand. Smooth bulk delivery enables teams to concentrate on manufacturing but not on supply. Reliability is needed in high-volume operations.

Product-Specific Fit

Chocolate candy pads are made to fit in as they have different shapes and weights. Chocolates placed properly will not be under pressure. This custom fit causes no smudging or deformation. It also increases visual symmetry within the box. Pads of matching product sizes increase the speed and precision of packing. Design Product-specific design enhances protection and presentation.

Interior Box Stability

Waxpapers wholesale are used to increase internal stability with the improvement of the base. They assist in the even distribution of weight and tidiness in the stacking during transportation. This stability results in less deformation of boxes. It is also resistant to vibration and the impact of candies. The gift boxes and shipping cartons are also areas where interior reinforcement should be boosted. Safety of delivery and customer satisfaction are also increased with stable interiors.

Quality Perception Boost

Properly designed candy pads will determine the perception of product quality to customers. Well-kept and organized interior is an indication of care and professionalism. Before tasting, customers tend to conclude on quality by just looking at it. The use of pads regularly also supports brand standards. Minor details such as this create loyalty and repeat business. Thought-provoking packaging would be value-added on top of the product.

Conclusion

Custom candy pads play a crucial role in confectionery products as a packaging component that promotes protection, structure, and presentation. They stabilize sweets and improve the look of the interiors to ensure that brands provide the same quality.

The design of pads in a thoughtful manner enhances efficiency, minimizes damage, and enhances perception by the customer. In a competitive market where every detail counts, investing in a well-crafted candy pad will secure the result of having an unfailing, high-quality and sleek opening of the box by the customers.

- Business

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- Technology

- Cryptocurrency

- Psychology

- Internet

- Ecommerce

- Family

- Others